admin

admin  2021-02-09 15:19:46

2021-02-09 15:19:46

Nowadays, with the development of industrialization, especially with the rise of the tertiary industry, the secondary industry is also constantly innovating, and the pressure sensor also benefits from this derived from the wireless pressure sensor.

So what is the working principle of the wireless pressure sensor?

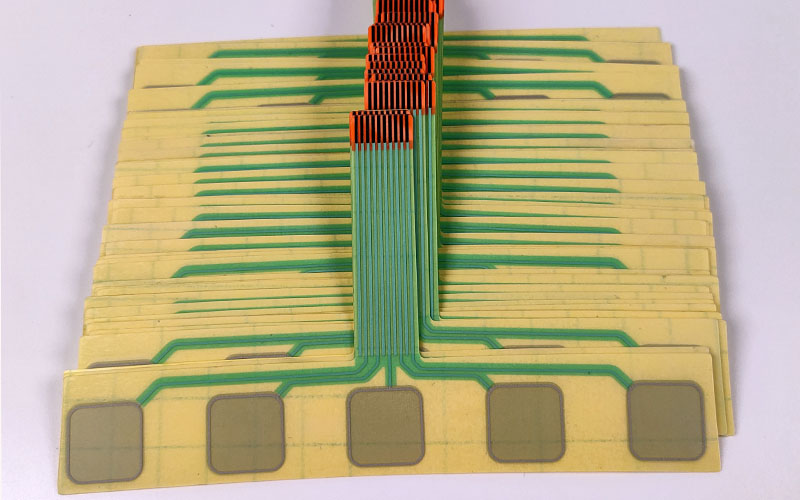

The wireless pressure sensor adopts the principle of piezoresistive strain. Its core component, the resistance strain gauge, is a sensitive device that converts the strain change on the test piece into an electrical signal.

Resistance strain gauge is one of the main components of the sensor. Usually the strain gauges are tightly bonded to the mechanical strain-generating matrix through a special adhesive. When the matrix is subjected to stress changes, the resistance strain gauges will also deform together, which changes the resistance value of the strain gauges, so that The voltage applied to the resistor changes. Such strain gauges usually produce relatively small resistance changes when subjected to force. Generally, these strain gauges constitute a strain bridge, so that the change in impedance is converted into a digital signal or an electrical signal.

This type of wireless pressure sensor is suitable for gas and liquid pressure measurement, even including sewage, steam, mildly corrosive liquids and gases.

Wireless pressure sensor is the most commonly used pressure sensor in industrial practice. It is usually used in hydrological monitoring and control systems; petroleum, chemical, environmental protection, and water pipe network monitoring; heating systems; medical equipment; smart water services; other automation and detection systems.

During monitoring, the pressure sensor can convert the pressure (generally the pressure of a liquid or gas) signal into an electrical signal output. The pressure electrical signal can also be used to measure the liquid level of a static fluid, so it can be used to measure the liquid level.