admin

admin  2020-09-25 16:14:41

2020-09-25 16:14:41

Capacitive touch technology is applied in a wide range of electronic products from smart phones, refrigerators and cars. In many applications, capacitive touch sensors provide input to a dedicated controller chip. The microcontroller directly participates in the MCU mold when the controller is integrated as a peripheral device.

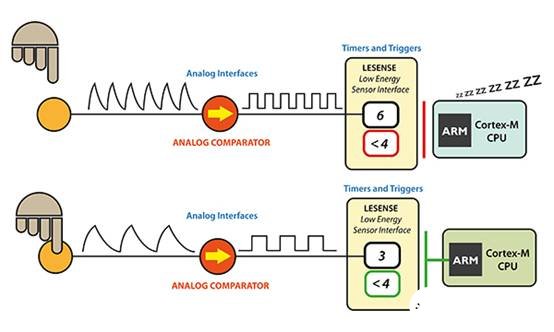

Regardless of whether the MCU has a sensor/controller circuit integrated on the chip, or if the touch sensor information is in a dedicated device, the MCU must deal with several problems created by capacitive touch input in order to achieve a satisfactory user experience. These include delay (for users to respond in time), accuracy and energy consumption. Energy consumption is a particularly important battery-powered device.

MCU vendors have provided a variety of capacitive touch solutions, from dedicated peripherals to ultra-low-power interfaces for battery-powered applications with capacitive touch sensors. After reviewing the solutions, however, a quick review of capacitive touch technology should be helpful.

Basic knowledge of capacitive touch

Generally, the current special design problems are no different from capacitive touch sensor sensors. Much of the complexity is due to the fact that the distribution characteristics of the electric field of sensors make their behavior "lumped elements" approximate inaccurate and misleading. To solve these problems, semiconductor companies have published many application notes that basically provide rules-if followed-will lead to a successful design. This article will focus on basic considerations; understanding some basic knowledge is essential to get the design started in the right direction.

Capacitive touch sensors can be roughly classified using simple spatial parameters:

Zero-dimensional sensor single-point contact response. A simple button is the most common implementation.

One-dimensional sensors can detect finger movement along a single, linear axis. Sliders and pulleys are the most popular implementations.

The two-dimensional sensor can detect finger movement along two axes. Touch screens and touch pads are good examples.

The technology is much more complicated, but, as always, the first important step in designing the end-user system is to select the type of sensor that corresponds to the application.

The most basic capacitive touch technology, one-dimensional and two-dimensional sensors rely on surface capacitance. One side of the panel is coated with conductive material, and the other side is insulating material. A small voltage is applied to the conductive layer to create a weak electric field. When a conductive finger or stylus touches the surface, a capacitor is generated instantly, which changes the electric field.

The sensor's controller can indirectly calculate the touch position by measuring the changes in capacitance from the four corner panels. The capacitance changes more, the closer the touch is to that corner. Surface capacitance technology has quite low resolution and causes capacitive coupling errors. For these reasons, it is commonly used in industrial controls and kiosks.