Medical field,Aerospace industry,Industrial applications,Environmental monitoring,Structural health monitoring ,etc..

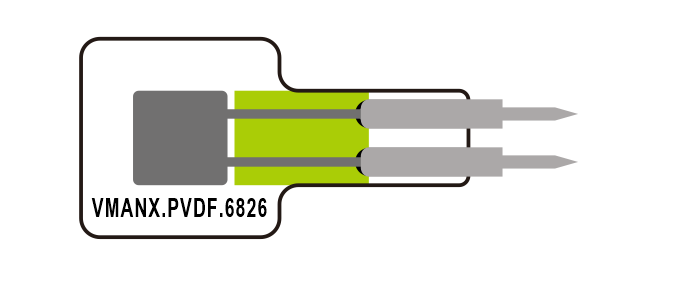

Product Specification:Unlock the power of precision sensing with vmanx PVDF-2268 Piezoelectric Sensor, engineered for a wide range of applications in industrial automation, robotics, and consumer electronics. This sensor harnesses the unique properties of piezoelectric materials to convert mechanical stress into an electrical signal, providing real-time feedback with exceptional accuracy and sensitivity .

High Sensitivity : Detect the smallest vibrations and pressure changes with a sensitivity rating that ensures reliable performance in critical applications.

Wide Frequency Response: Designed to operate effectively across a broad frequency range, making it ideal for dynamic applications, including monitoring machinery vibrations and detecting impact forces.

Durable Construction: Built to endure harsh environments, our piezoelectric sensor features a robust design that resists moisture, dust, and extreme temperatures, ensuring longevity and consistent performance.

Compact and Lightweight: Its sleek design allows for easy integration into various systems without compromising space or adding excessive weight.

Versatile Applications: Perfect for use in industrial equipment, automotive systems, medical devices, and consumer electronics, making it a versatile choice for engineers and developers.

Easy Integration: The sensor comes with standard electrical connections and detailed documentation, enabling simple integration with existing systems and platforms.

Applications:

Piezoelectric Thin Film Sensor Technical Manual :

As an actuator, polymers' low acoustic impedance allows them to be effectively used to deliver energy to air and other gases.

Table 1. Typical characteristic parameters of piezoelectric films

|

Symbol |

Parameter |

PVDF |

Interpolymer |

Unit |

|

T |

Thickness |

44-220 |

Various |

um(micron,10-6) |

|

d31 |

Piezoelectric strain constant |

23 |

11 |

|

|

d33 |

|

-25 |

-30 |

|

|

g31 |

Piezoelectric stress constant |

216 |

162 |

|

|

g33 |

|

-330 |

-542 |

|

|

k31 |

Electromechanical coupling constant |

12% |

20% |

|

|

Kt |

|

14% |

25-29% |

|

|

C |

Capacitance |

380(28μm) |

68(100μm) |

PF/cm2@1kHz |

|

Y |

Young’s modulus |

2-4 |

3-5 |

109N/m2 |

|

V0 |

Speed of sound tensile thickness |

1.5 2.2 |

2.3 2.4 |

103m/s2 |

|

P |

Thermoelectric coefficient |

30 |

40 |

10-6C/m20K |

|

E |

Dielectric constant |

106-113 |

65-75 |

10-12F/m |

|

ε/ε0 |

Relative dielectric constant |

12-13 |

7-8 |

|

|

ρn |

Mass density |

1.78 |

1.82 |

103kg/m |

|

ρe |

Volume resistivity |

>1013 |

>1014 |

Resistance meter |

|

R R |

Surface metallization resistivity |

2.0 |

2.0 |

Ω/square(CuNi) |

|

|

|

0.1 |

0.1 |

Ω/square(Ag ink) |

|

tan |

Loss tangent |

0.02 |

0.015 |

@1kHz |

|

|

Yield strength |

45-55 |

20.30 |

106N/M2(tensile axis) |

|

|

Temperature range |

-40-80 |

-40 to 115...145 |

℃ |

|

|

Water absorbency |

<0.02 |

<0.02 |

%H2O |

|

|

Maximum working voltage |

750(30) |

750(30) |

V/mil(V/μm),DC,@25℃ |

|

|

Breakdown voltage |

2000(80) |

2000(80) |

V/mil(V/μm),DC,@25℃ |

Table 2 Comparison table of piezoelectric materials

|

Characteristic |

Unit |

PVDF thin film |

PZT |

BaTiO3 |

|

Density |

103kg/m3 |

1.78 |

7.5 |

5.7 |

|

Relative dielectric constant |

ε/ε0 |

12 |

1.200 |

1.700 |

|

d31 constant |

(10-12)C/N |

23 |

110 |

78 |

|

g31 constant |

(10-3)Vm/N |

216 |

10 |

5 |

|

k31 constant |

% at 1kHz |

12 |

30 |

21 |

|

Acoustic impedance |

(106)kg/m2-sec |

2.7 |

30 |

30 |